PrintoLUX Signo Metal and Plastic Labeling System

The patented PrintoLUX process enables the creation of durable, high-resolution labels and signs on metals, plastics and foils – fast, flexible and industrial-grade.

Choose your material

Eleven material options available, including aluminium, stainless steel, polyamide, and adhesive films.

Pre-treatment

A primer is applied to ensure strong ink adhesion during thermal processing.

Printing

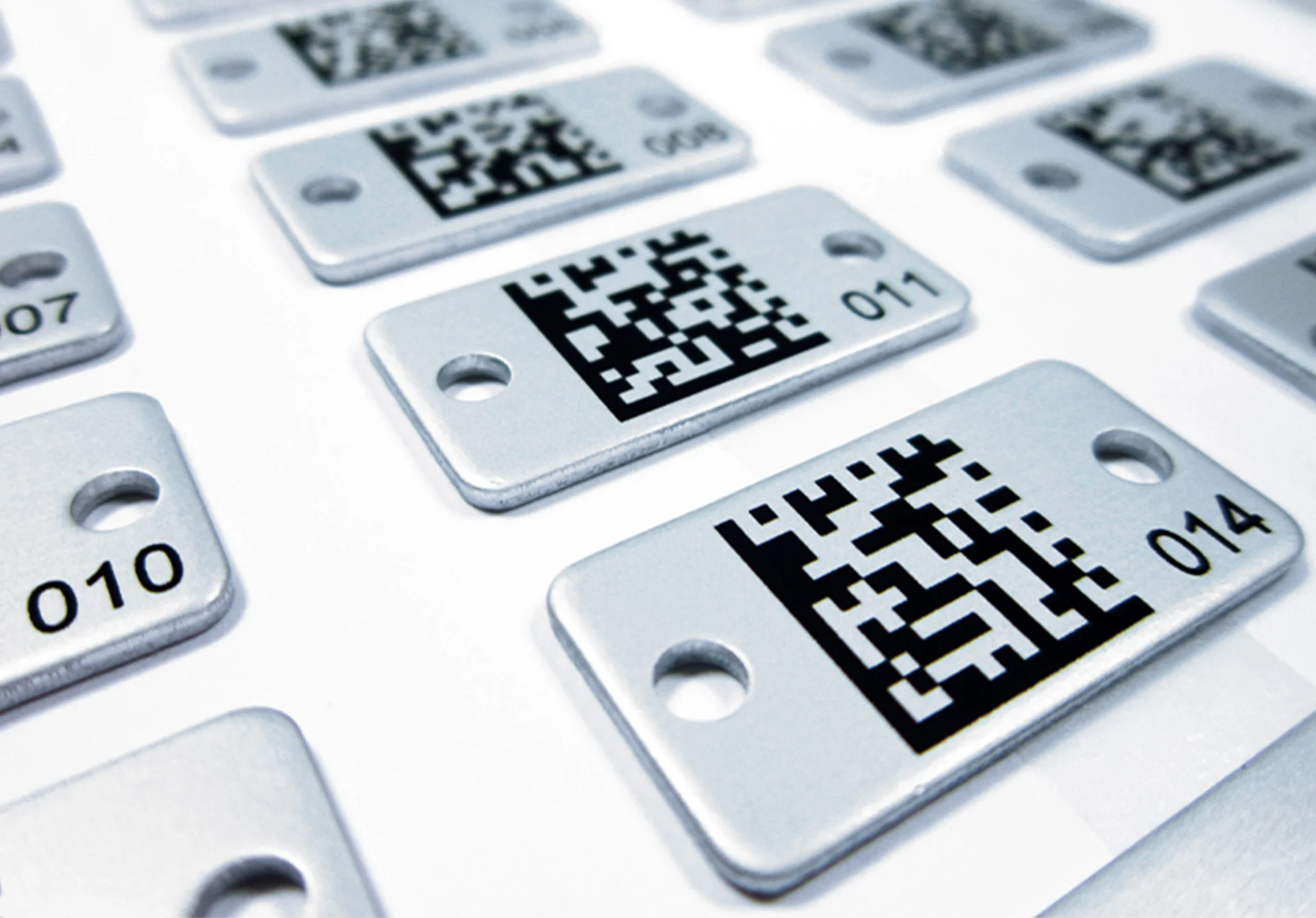

Print text, logos, graphics, 2D codes and colour elements – fully customisable.

Thermosetting

Final curing ensures immediate use and exceptional durability.

Applications

- Cable labels

- Equipment signs

- Type plates

- Safety signs

- Pipeline labels

- Scales and dials

- Front panels and enclosures

- And many more...

Industries

- Automotive

- Machine and plant engineering

- Chemistry and pharmaceuticals

- Energy industry

- Aerospace

- Maritime industry

- Logistics

- Food industry

- Botanical Gardens, Zoos and Museums

- Hospitals

The latest generation of PrintoLUX® labelling systems offers a print area of 204 × 291 mm (borderless) and prints on material up to a thickness of max. 7.0 mm.

Thanks to its compact design, the system is ideal for use in offices or workshops where space is at a premium.

With PrintoLUX®, your own short-term labelling needs can be produced just in time. In total, the following 11 materials can be printed with the PrintoLUX® process:

- Aluminium, silver (AE)

- Aluminium, white (ASE)

- Stainless steel (VE)

- Brass (ME)

- Aluminium composite material (AV)

- Polyamide (PA)

- Polyester decorative foil (PD)

- Polyester adhesive foil (PK)

- Polyester foil (PY)

- Laminate material (SP)

- Document adhesive foil (DK)

The ink system is managed by a total of 4 cartridges. Like all PrintoLUX® labelling systems, only environmentally friendly, water-based inks are used. No hazardous waste is generated during production with PrintoLUX®.

For the initial equipment of our customers, we deliver the PrintoLUX® labelling system with all additionally required components such as software, consumables and heating unit. In addition, instruction on the handling and operation of the process takes place in form of user training.